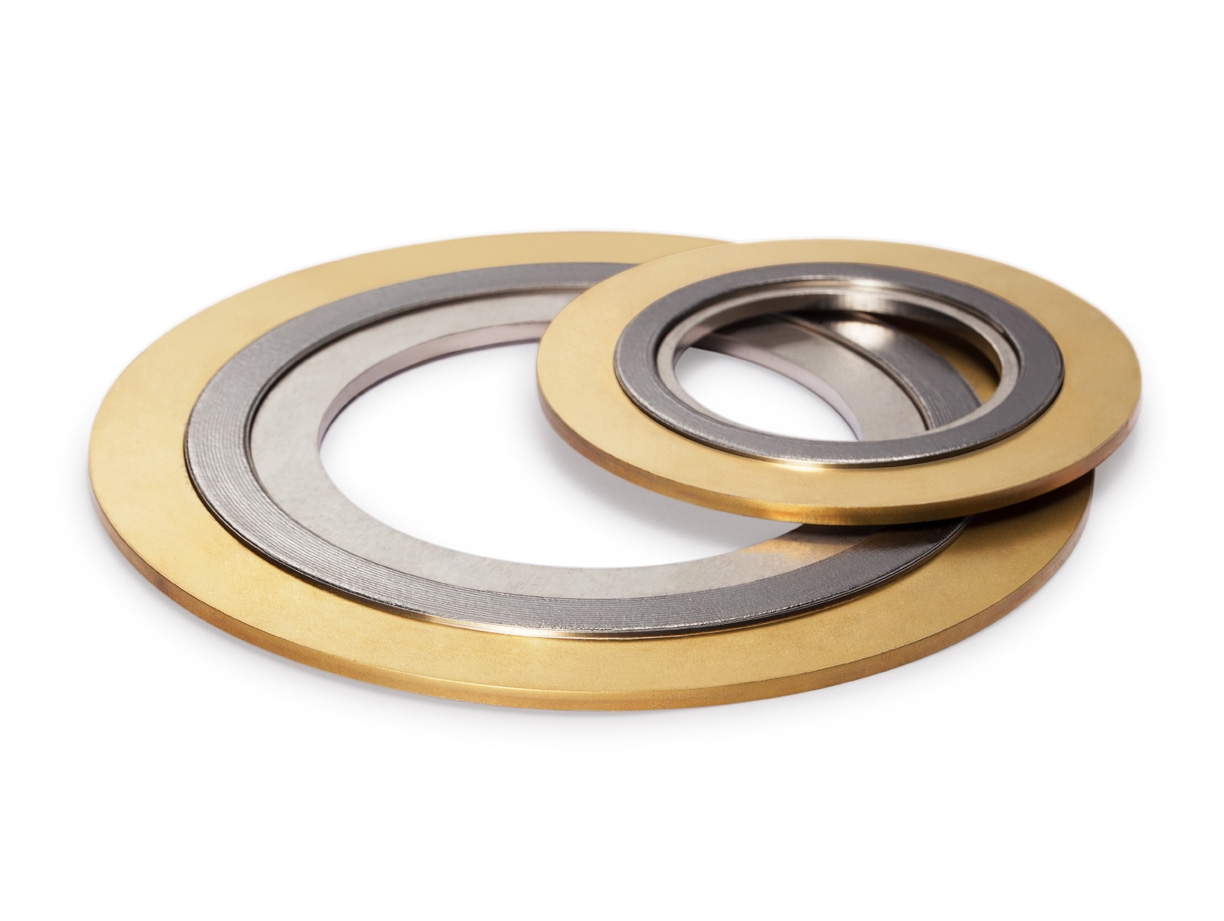

Spiral wound gaskets, various shapes and sizes, standard and non-standard according to customer request.

The use of these gaskets is recommended for applications with severe requirements, rated pressures higher than PN40 (600 #) and high temperature, dangerous or aggressive fluids for which the use of soft gaskets is impossible or does not guarantee reliability and sealing.

These can be:

- With outer ring and inner ring

- With outer ring, it is designed to center the gasket between the flanges and to provide the gasket with increased mechanical strength. This ring is thinner than the sealing package thickness and is made of carbon steel protected by zinc or paint coating. The ring also ensures that the sealing package will not be tightened excessively, limiting the minimum thickness of the gasket during installation.

- With inner ring, it improves the mechanical resistance of the gasket and in the same time achieves the alignment of the ID of the gasket with the ID of the flange. This way it can be avoided the turbulent flow in the gasket area and direct contact between the metal strip and the working fluid, protecting them from high temperature and pressure variations. Usually, the inner centering ring is made of stainless steel that resists the action of the working fluid. Upon request, the ring can also be made from other materials. The thickness of the inner centering ring is the same as the thickness of the outer centering ring. It is used for flanges with profiled sealing surfaces (TG etc.).

- Without rings, it can be used for flanges with profiled sealing surfaces (TG etc.).