TECHNOSEAL SERVICES SRL can provide a wide range of metallic and semi metallic gaskets as authorized distributor on Romanian market for the following metal gasket manufacturers: Donit TESNIT, d.o.o. , Flexitallic Ltd and SPETECH Sp. z o.o.

1. Spiral wound gaskets, various shapes and sizes, standard and non-standard according to customer request.

The use of these gaskets is recommended for applications with severe requirements, rated pressures higher than PN40 (600 #) and high temperature, dangerous or aggressive fluids for which the use of soft gaskets is impossible or does not guarantee reliability and sealing.

These can be:

2. Metal Jacketed Gaskets

The metal jacketed gaskets are made of a metallic layer on exterior with a soft filling material.

The filler material offers outstanding compressibility and resilience, while the metal coating guarantees excellent resistance and protects the soft material against pressure, temperature fluctuations and corrosion. The metal jacketed gaskets can be produced in a variety of configurations and are ideal for heat exchangers.

3. Kammprofile gaskets are made of a metallic core with concentric ribs over which it is applied a graphite foil.

These gaskets are designed for equipment with flange joints (heat exchangers) and can successfully replace metal jacketed gaskets.

From a technical point of view, these gaskets are capable of working in a wide range of tightening pressures (from 20 up to 500 MPa, with a 90 MPa optimum) compared to metal jacketed gaskets which work in a smaller range (from 100 up to 250 MPa, with a 160 MPa optimum).

The maximum working temperature is similar to the spiral wound gaskets and the installation requirements are less severe.

These gaskets can be reused after replacing the graphite foil, process which can be performed in a short time with minimal cost to the beneficiary.

From an economic point of view, the long-term cost for kammprofile is significantly lower than the cost of other technical solutions, not only the initial purchase value, but also the cost of refurbishing it at least 5 times.

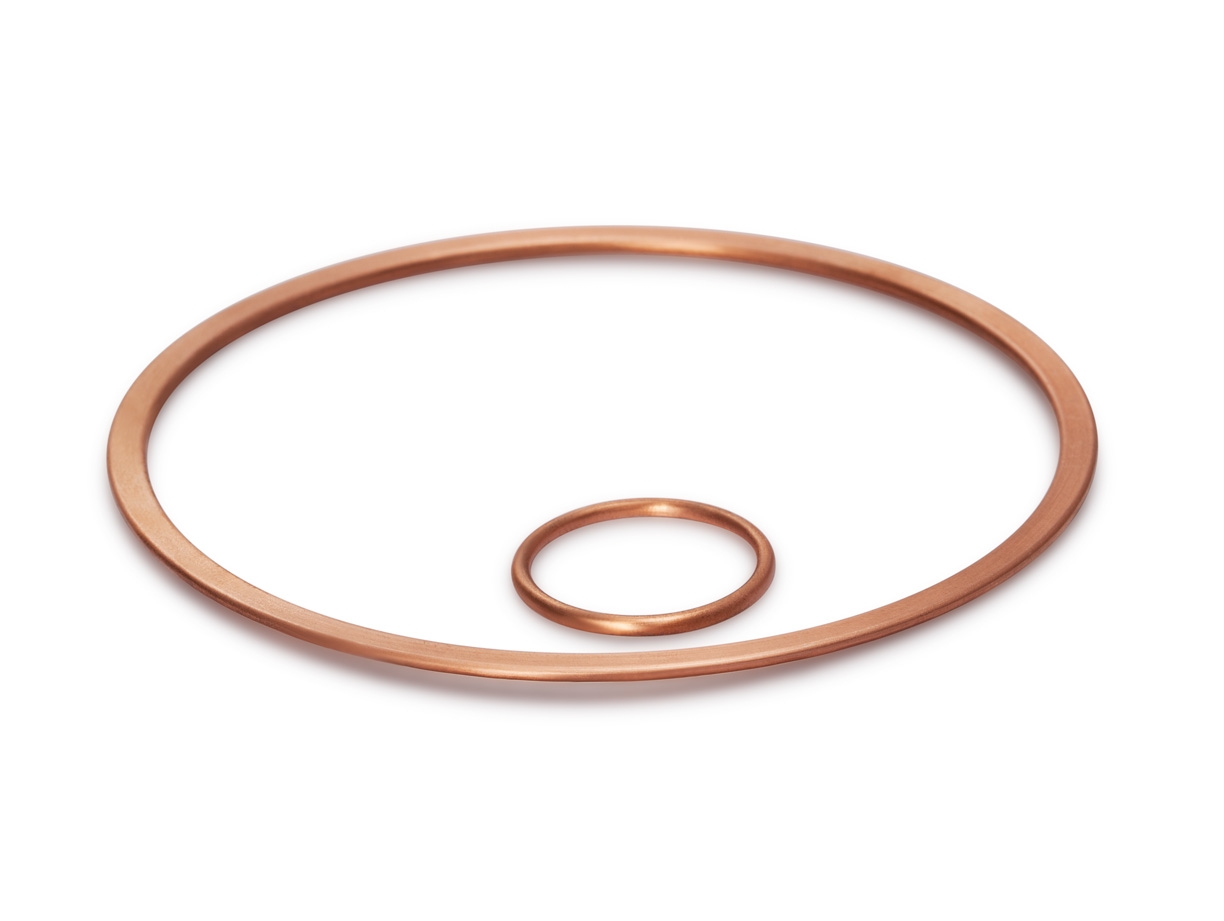

4. Corrugated gaskets, this type of gaskets is made of a metal ring coated with graphite, PTFE or Mica, depending on the application.

Maximum sealing fluid temperature: 800°C.

Maximum sealing fluid pressure: 350 bar;

5. Ring Type Joints (RTJ) are gaskets for applications with very severe requirements, which are mounted in flanged joints with special sealing surface.

For example: type R rings with oval or octagonal section, RX or BX or lenticular gaskets.

Joint types are mainly used in petroleum, gas, petrochemical and chemical industries for specially sealed flanges exposed to high temperatures (up to 1000 °C) and high pressures (up to 1500 bar).

Dimensions according to ASME B16.20 or API Std. 6A.

The material of the ring will be specified by the customer.

6. Special gaskets type: weld ring, lip seals, metal diaphragms, baffle seals, double cones.